Air Bearing Axis

An air bearing axis is a system that uses compressed air to provide a smooth and precise means of movement for semiconductor equipment. It uses a thin stream of compressed air to cushion the equipment as it is lifted or moved, minimizing friction and wear. This type of system is commonly used in semiconductor manufacturing processes, particularly those that require high precision and delicate handling of equipment. It allows for greater control and flexibility in the movement of the equipment, and can also help to reduce downtime and maintenance costs. Suitable for various precision measurement processes, Precise alignment.

Class 1 clean room compatible. Stroke is 50mm to 500mm. The encoder can be selected from 1um to 0.05um depending on the application. Straightness and flatness are 0.5um/300mm. Pitching and yawing can be delivered with +/-2 arc sec coils, magnets, and encoders all installed.

Easy to achieve ultra-high six degrees of freedom (linear accuracy, horizontal straightness, vertical. Zero wear, zero maintenance.

Repeat +/-0.2μm/300mm accuracy

Speed Ripple 100mm/s 0.1% %

Nanoscale Straightness 0.5 % μm/300mm

Degree of freedom Yaw +/-2 arc sec

Applicable industries

- Semiconductor

- Detection

- Automated precision measurement and laser cutting.

- Ideal for clean room and medical applications.

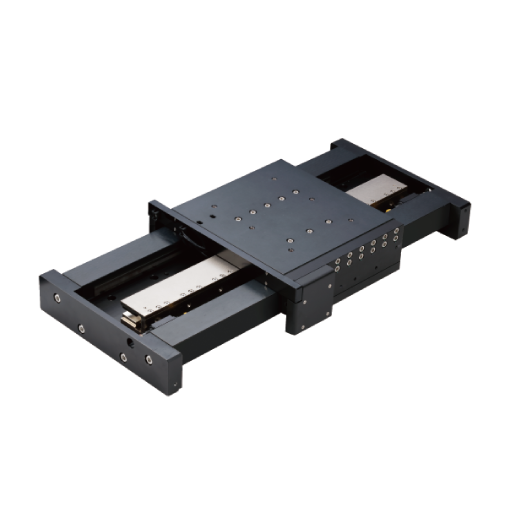

LBT-275 series

| Stroke | 50~500 (every 50mm) (mm) |

| Positioning accuracy | +/-0.15~+/-10 (N) |

| Repeated positioning accuracy | +/-0.1~+/-1(um) |

| Rated thrust | 139 (N) |

| Maximum thrust (mm) | 695 (N) |

| Standard stroke | 50~500 (mm) |

| Maximum speed | 2 (mm/s) |

| Straightness/Flatness | +/-1.5/+/-3(um) |

| Encoder resolution | 1~0.05(um) |

| Payload capacity | 50 (kg) |

| Air consumption | <35 (L/min) |

LBT-210 series

| Stroke | 50~500 (every 50mm) (mm) |

| Positioning accuracy | +/-0.15~+/-10 (N) |

| Repeated positioning accuracy | +/-0.1~+/-1(um) |

| Rated thrust | 139 (N) |

| Maximum thrust (mm) | 695 (N) |

| Standard stroke | 50~500 (mm) |

| Maximum speed | 2 (mm/s) |

| Straightness/Flatness | +/-1.5/+/-3(um) |

| Encoder resolution | 1~0.05(um) |

| Payload capacity | 50 (kg) |

| Air consumption | <35 (L/min) |